SP&S #273

Astoria RR

Work Photos

Early Photos

History

Events

Join

ARPA

Links

Contact Us

|

|

|

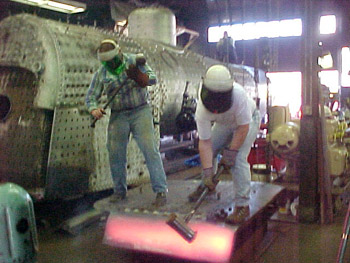

Flanging the Backhead

Tuesday, June 5, 2001 by Martin AdamsWork on the back of the boiler is progressing carefully and steadily. We have built a die to flange the compound radius bends in the backhead (outside, back of the firebox) sheet. A special thanks to Bergerson Construction for giving us a couple pieces of 12" H beam to build this die. The replacement sheet, which has been predrilled for all of the staybolts holes, was securely bolted to the die. Then the fun began. Using 2 oxygen-propane heating torches, capable of producing 1 million BTU's each, we heated the 1/2" thick sheet where it was to be bent (flanged) over the die. Once the sheet was orange hot, we hammered the sheet over the die with special 20 pound sledge hammers with hardwood faces. Thanks to Ed Overbay for supplying the wood that was able to stand this kind of punishment.

This was a very exhausting experience as once the plate was up to heat, the hammering had to start immediately and could not stop until the flanging was finished, resting tightly on the die. To give you an idea of the heat, each torch uses one bottle of oxygen every 7 minutes. Just flanging this one sheet one can get an appreciation of the men who originally built these locomotives. Yes, the method we used to flange the backhead, is exactly how they did it in the "old days" at the Baldwin Locomotive Works. The only difference, they did it 10 hours per day, 6 days a week.

We have also constructed a die to form the doorway in the backhead sheet. This will be formed in the same manner as above initially, but will be finished to the exact size with the help of a large hydraulic press. We're hoping all the flanging will be complete and the backhead installed on the boiler ready for welding and riveting by the July 15th open house.

More Photo NEWS